ASTANA — Deep within a restricted-access facility in Astana, where molten metal is forged into 12-kilogram bars of 99.99% purity, known as “four nines” gold, the mission goes far beyond jewelry or display. Each bar plays a vital role in reinforcing Kazakhstan’s national reserves, a process that metallurgists say weighs more than gold itself.

The refinery processes only domestic raw materials, including dore alloys, ligature, placer, cathode gold, and recycled jewelry. Photo credit: Kazinform Click to see the map in full size. The map is designed by The Astana Times.

One of the men behind this demanding operation is Symbat Muratbekov, a first-generation metallurgist from Oskemen in the East Kazakhstan Region. He chose the profession himself, studying on a government grant. He has been living in Astana with his wife and three children for two years, working daily where molten metal is transformed into pure gold.

“This job is for real men. Strong and patient. Here, a lot depends on the team spirit. For me, this is a second family,” Muratbekov said, as quoted by Kazinform news agency.

After 15 years in the industry, he said he no longer fears the fire or the weight of the task. Each bar represents teamwork, trust and responsibility. While the furnace halls are primarily male-dominated, women play key roles in laboratories and administration, ensuring no detail is missed.

Strict access and stringent security

Symbat Muratbekov, a first-generation metallurgist from Ust-Kamenogorsk. Photo credit: Kazinform

The refinery enforces tight security. No jewelry, phones, or personal items are allowed beyond the entrance. Even protective clothing and shoe covers are incinerated after a shift to ensure no trace of gold leaves the site. The electrochemical purification process eliminates unnecessary emissions and waste.

Outside visitors, including journalists, are rare. If allowed in, they must wear gloves when handling gold bars – not for cleanliness, but because pure gold is delicate. A single scratch reduces its value.

Kazakhstan’s gold, refined in Kazakhstan

The refinery processes only domestic raw materials, including dore alloys, ligature, placer, cathode gold, and recycled jewelry. Before any gold enters production, it is verified in the laboratory. Then the journey begins in the hot shop, where impurities are separated through melting, and the metal is cast into anodes for electrolysis. It is a process that transforms the raw product into nearly flawless metal.

Each bar plays a vital role in reinforcing Kazakhstan’s national reserves, a process that metallurgists say weighs more than gold itself. Photo credit: Kazinform

During electrolysis, gold anodes, with a purity of 92%, are immersed in acidic baths, and titanium cathodes are used. An electric current dissolves the metal, allowing pure gold ions to travel through the solution and deposit as crystals on the cathode. Impurities either dissolve or settle separately.

This method, free of excessive remelting, is what makes it possible to produce so-called bank-grade gold with 99.99% purity.

Precision casting with zero margin for error

After purification, the gold is melted again in a granulator furnace. Unlike manual pouring, which allows for slight deviations in weight, this technology ensures that exactly 12 kilograms of granules are placed into graphite molds before entering a tunnel furnace.

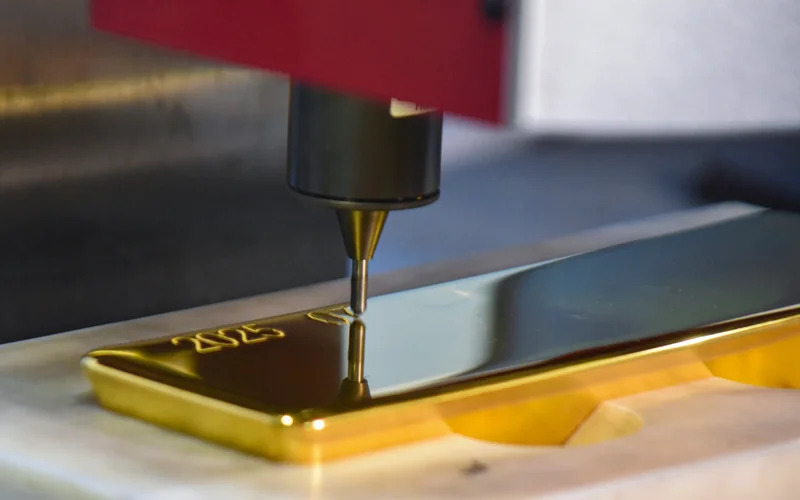

The final step is engraving. Since 2022, this has been done by an automated dot marker, which etches data precisely according to state standards. Photo credit: Kazinform

The final casting phase, conducted at 1,200 degrees Celsius, lasts 20 minutes. The resulting bars are then steamed, wiped with alcohol, and polished. Each is examined meticulously for chips, dents, or scratches. Any defect sends the bar back for remelting, though this is rare.

Etching the identity of gold

The final step is engraving. Since 2022, this has been done by an automated dot marker, which etches data precisely according to state standards.

“Here, you can see everything: the year, month, batch number, and serial number. Two stamps are mandatory – the plant stamp and another marked ‘Kazakhstan,’ so everyone knows this gold is ours,” said Ruslan Seisenbekov, head of finished product operations.

All refined gold goes directly to the National Bank of Kazakhstan, the sole customer. A symbolic quota, however, is reserved for jewelers, who can buy up to 100 grams of granules per purchase.

Production by the ton, responsibility by the gram

Zekail Tulyubaev. Photo credit: Kazinform

The refinery, located in Industrial Park No. 1 in Astana, produces between four and five metric tons of gold per month, depending on orders.

“This is a heavy and honest metal (…) There is no room for deception here. And the people here are the same,” said technical director Zekail Tulyubaev.

According to Tulyubaev, 80 people currently work at the plant. Since its launch in 2013, no workplace accidents have been reported. The plant is monitored by surveillance and guarded 24 hours a day.

Asked whether there had been any theft attempts, the security service firmly denied it.

“It is impossible to smuggle gold out. The control and security systems are designed to stop any attempt immediately,” Tulyubaev said.

“What truly protects it is not just technology, it is the honesty of the people. Gold chooses those who are worthy. It does not tolerate dishonest hands,” he added.

All refined gold goes directly to the National Bank of Kazakhstan, the sole customer. Photo credit: Kazinform

Visitors also undergo multiple screening stages, including scanning for even the tiniest traces of metal. If a guest wears personal jewelry into the facility, they cannot leave with it, as detectors will activate, and they must forfeit their items. Even gold dental crowns must be declared in advance.

Filming is strictly forbidden.

Turning waste into wealth

The refinery has two dedicated waste processing shops. The first, long-operating facility burns and recycles everything that has come into contact with precious metals, including clothing, filters, and gear. The second, launched in late 2023, processes slag and thermal waste, yielding gold- and silver-rich concentrates. This both boosts profits and reduces environmental impact.

While the furnace halls are primarily male-dominated, women play key roles in laboratories and administration, ensuring no detail is missed. Photo credit: Kazinform

For Muratbekov and his colleagues, gold is more than just a commodity. “Gold allows only the honest and hardworking to get close. That is what they taught in the East,” he said.

“It is not easy here. The shop is loud and the work is tough, so our distinct quality is not just endurance, it is having a loud voice,” Muratbekov added.

While the furnace halls are primarily male-dominated, women play key roles in laboratories and administration, ensuring no detail is missed. Photo credit: Kazinform

The factory cast its 30,000th gold bar on Metallurgist Day on July 20, a milestone that honors not only production but also the dedication behind every gleaming “brick.”

The article was originally published in Kazinform